Plastics manufacturing focused on the customer

Each new component is developed in co-design with the customer to achieve the best result in terms of quality, cost and productivity. UNICA MULTI-MATERIAL PLASTIC MOLDING does not limit itself to the sole production of the object, but offers the Customer a complete service: feasibility study, industrialisation, cost analysis, process engineering, verification of functional characteristics and quality requirements, pre-series moulding, component homologation and mass production.

Finally, we are also able to guarantee additional services such as customisation and assembly.

Mold design

Mold design

The feasibility study of plastic products is the first and most important work phase at Unica, and is set to verify the feasibility of the project and provide answers to the technical specifications of the product.

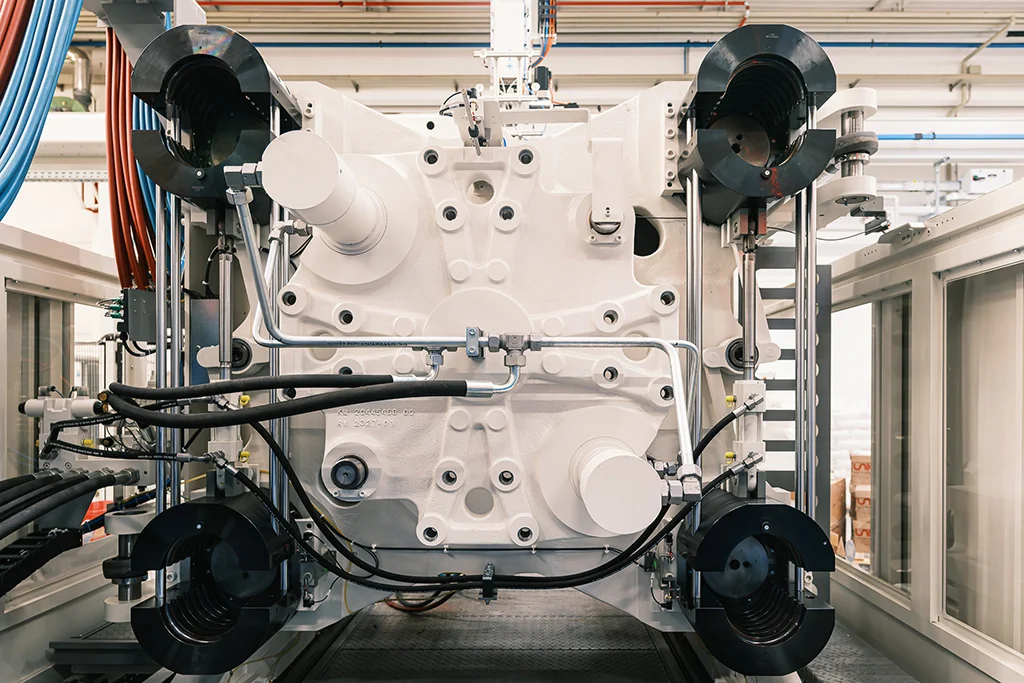

Mold making

Mold making

each element contributes to the making of moulds for components destined for various sectors such as home appliances, electronics and others.

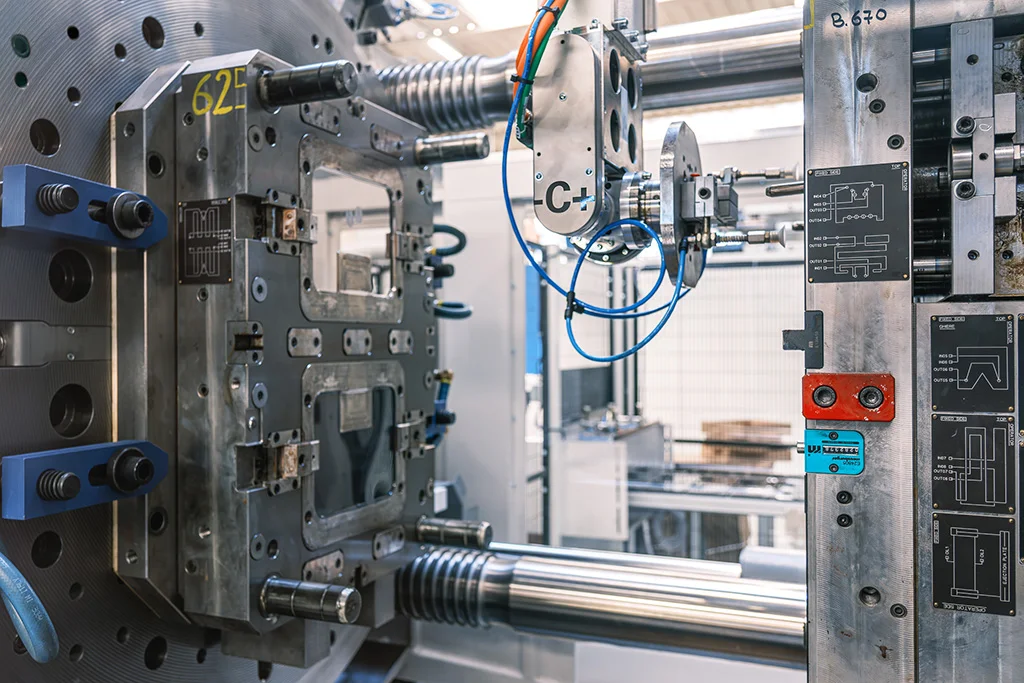

Injection molding

Injection molding

Da più di trent'anni ci occupiamo di stampaggio di materie plastiche utilizzando diverse tecnologie e lavorazioni

Customisation

Customisation

Offriamo un servizio aggiuntivo per la decorazione dei prodotti. Le applicazioni tecniche utilizzate in questo campo sono diverse a seconda delle necessità espresse.

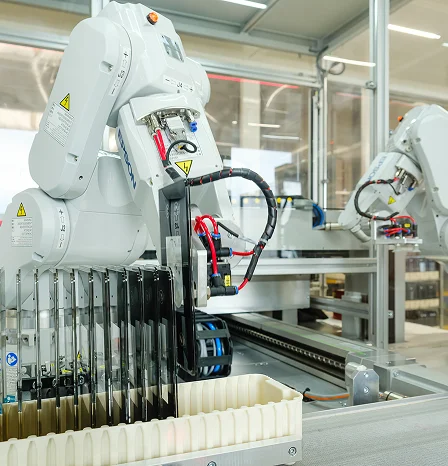

Assembly

Assembly

A dedicated department carries out assemblies of highly aesthetic and functional components, either manufactured in-house or purchased externally.

Mold design

From the idea to the project: Feasibility study and FEM analysis

The feasibility study of plastic products is the first and most important work phase at Unica, and is set to verify the feasibility of the project and provide answers to the technical specifications of the product. This phase requires great attention to detail, maximum listening to the needs and objectives of the customer involved in the co-design of the product from the very beginning.

- Provide FEM filling and deformation analysis of the plastic product, which makes it possible to avoid numerous mould set-up steps, thus shortening the time to market of the mould.

- Design the mould using state-of-the-art 3D CAD, handling any type of file and format.

Mold making

our customized solutions

Experience, technology, logistics: each element contributes to the making of moulds for components destined for various sectors such as home appliances, electronics and others. We have an international network of qualified suppliers, which allows us to achieve maximum flexibility and guarantee compliance with mould delivery schedules and the best quality/price ratio. All stages of the mold-making process are supervised by UNICA MULTI-MATERIAL PLASTIC MOLDING: product engineering and development in co-design with the customer to optimise functionality, aesthetics and productivity, mould design, project control and approval, mould construction, testing and final tuning.

Injection molding

Comparing technologies: over-moulding, index moulding and two-injection moulding

The moulding department, with presses from 40 to 1500 tonnes equipped with cartesian and anthropomorphic robots, uses various technologies and processes: single-material moulding, overmoulding, two- and three-material moulding with index system, rotary table, robot transfer, co-moulding, compression injection moulding.

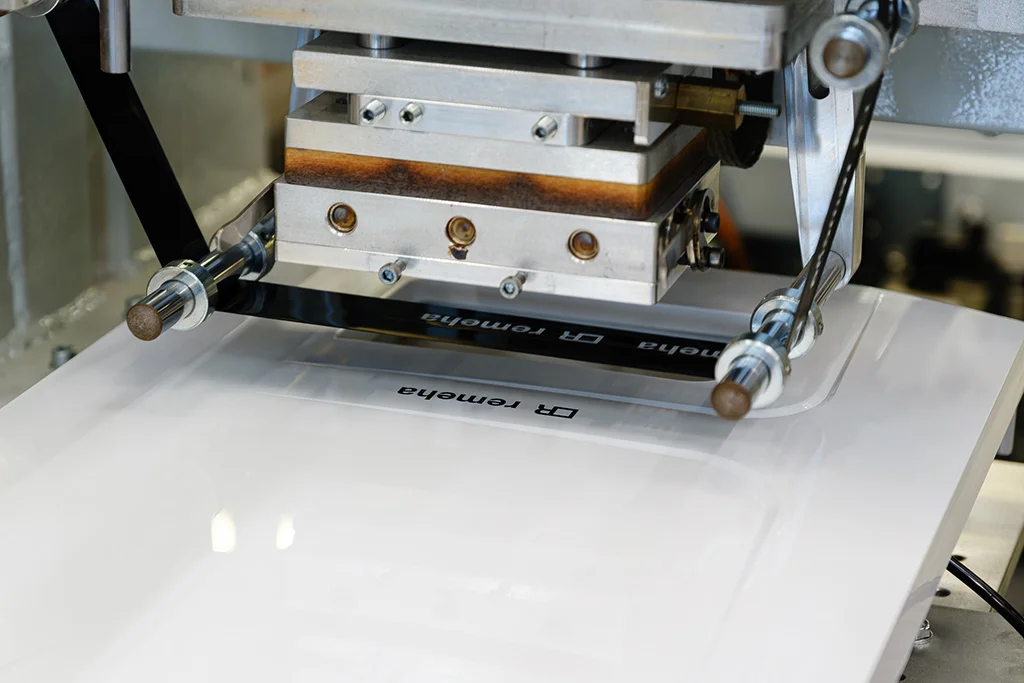

Customisation

Colour and transparency: silk-screen printing, pad printing and hot stamping, laser engraving

Our company offers customers an additional service: the customisation of products with different technological applications according to the needs expressed by the customer.

Silk-screen printing

Screen printing is a well-established industrial printing technology, widely used in all applications where a higher ink thickness than other printing technologies available today is required with better opacity and colour rendering results. UNICA MULTI-MATERIAL PLASTIC MOLDING has equipped itself with a clean room to handle high-precision screen printing in a controlled atmosphere environment.

Pad Printing

Pad printing is an indirect printing process that makes it possible to reproduce, with high fidelity and resolution, lettering and decorations both on flat surfaces and on concave, convex or otherwise irregular surfaces. It can be defined as a system that allows 2D graphics to be transferred onto 3D objects and surfaces. Pad printing allows printing with a higher definition than screen printing, enabling the reproduction of the finest strokes with sharpness, even in multiple colours.

Hot stamping and transfer

Hot stamping is a typographic printing system that relies on the combined use of heat and pressure. The technique has the great advantage of eliminating ink from the printing process, replacing it with foil (thin multilayer film). In the case of transfer, pre-printed images or graphics are transferred. Hot foil stamping is therefore an environmentally friendly process.

Laser engraving

Laser Engraving is based on the principle of using a beam of laser light to change the surface characteristics of the material by vaporising it locally and removing material, passing the beam over the surface several times to obtain cavities with well-defined geometric properties.

Assembly

The finished product

A dedicated department carries out assemblies of highly aesthetic and functional components, either manufactured in-house or purchased externally.